1. Automatic Powder Coating Spray Gun Components

Automatic Powder Coating Spray Guns feature robotic arms, precision nozzles, electrostatic generators, and programmable controllers. Advanced models integrate IoT sensors for real-time adjustments and closed-loop powder recovery systems to minimize waste. These systems ensure consistent coverage on complex parts like automotive frames or machinery components.

https://www.hpowdercoating.com/pcg.html

2. Applications of Automatic Powder Coating Spray Guns

Ideal for high-volume industries such as automotive, appliance, and aerospace manufacturing, these guns coat car bodies, refrigerators, and aircraft parts. They excel in repetitive tasks, delivering uniform finishes on assembly lines while reducing labor costs.

3. Automatic Powder Coating Spray Gun Pricing

Prices start at 15,000forentry−levelsystemsandexceed150,000 for fully automated robotic setups. Mid-range models (40,000–80,000) from brands like Gema or Sames Kremlin offer customizable settings and faster production cycles.

4. Using Automatic Powder Coating Spray Guns Correctly

Program spray paths via the control interface, set voltage (50–100 kV), and maintain a 10–15 cm spray distance. Optimize powder flow rates and monitor recovery systems to reduce overspray. Cure coated parts at 400°F for maximum durability.

5. Choosing the Best Automatic Powder Coating Spray Gun

Prioritize systems with multi-axis mobility for intricate designs. Select models with self-cleaning nozzles and IoT connectivity for predictive maintenance. Ensure compatibility with epoxy, polyester, or metallic powders.

6. Safety for Automatic Powder Coating Spray Guns

Install explosion-proof ventilation to manage combustible dust. Ground all equipment to prevent static sparks. Inspect robotic joints weekly and train operators on emergency shutdown protocols.

7. Efficiency of Automatic Powder Coating Spray Guns

Automated systems cut labor costs by 50% and material waste by 35% compared to manual methods. Energy-efficient designs reduce power consumption, while modular components streamline repairs.

8. Automatic Powder Coating Spray Gun Q&A

Q: Why invest in automatic over manual spray guns?

A: Automation ensures faster production, consistent quality, and lower long-term costs.

Q: Can these guns coat non-conductive materials?

A: No—powder adhesion requires conductive surfaces like metals.

Q: How to maintain robotic coating systems?

A: Clean nozzles daily, update software, and replace worn parts quarterly.

Q: Are compact automatic systems viable for small shops?

A: Yes, benchtop models suit low-volume, high-precision tasks.

Q: How to reduce powder waste?

A: Use closed-loop recovery systems and calibrate spray patterns regularly.

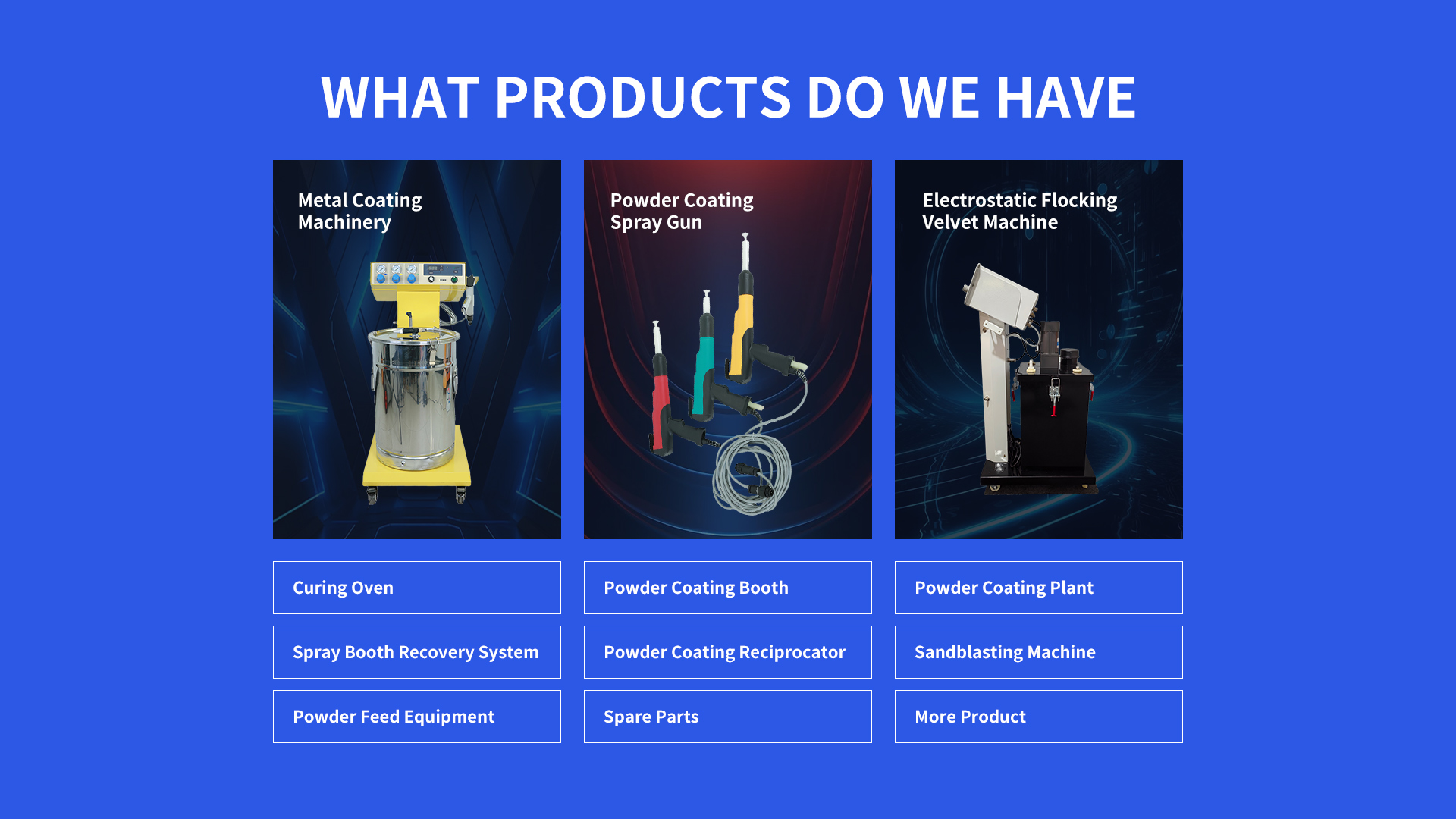

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com